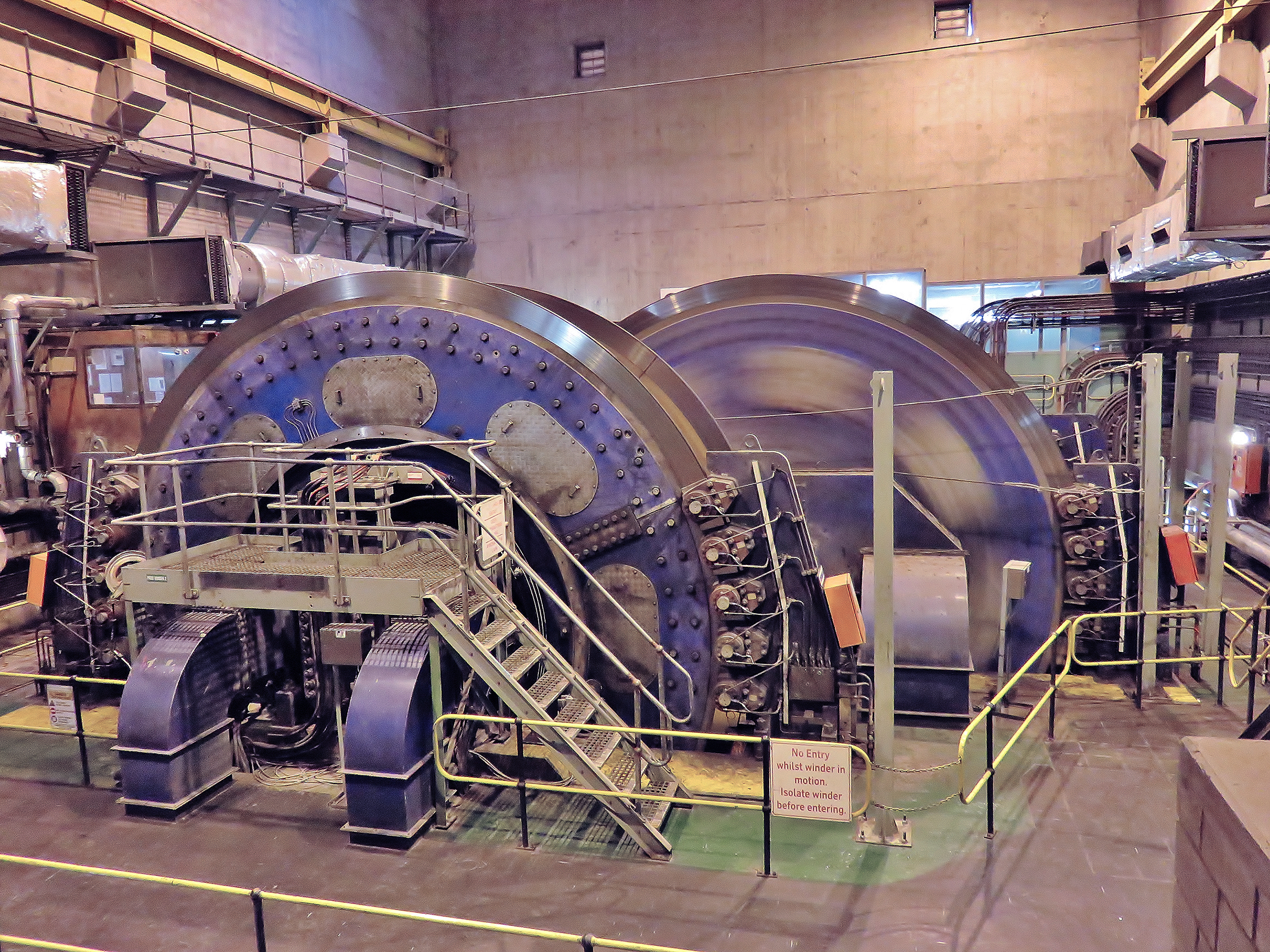

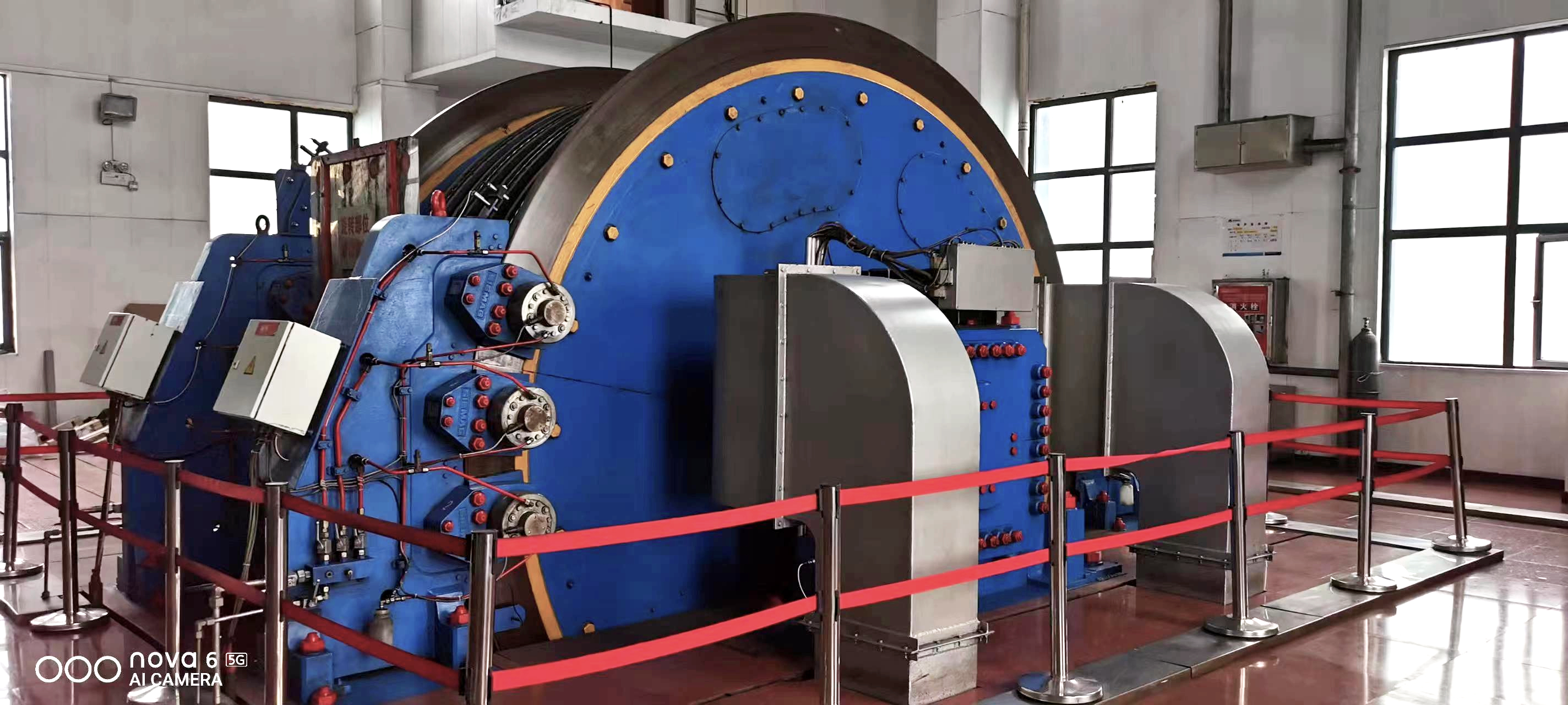

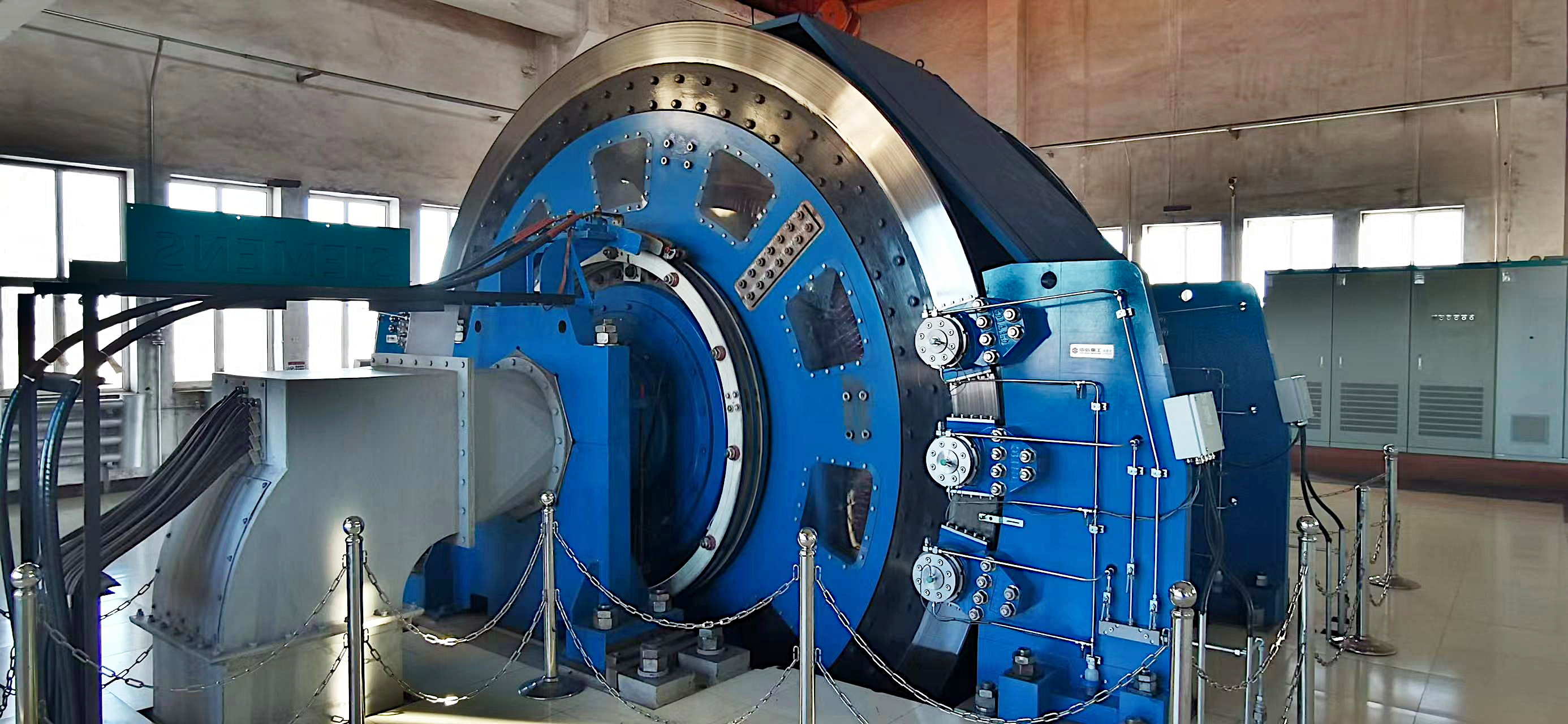

Koepe integrated

An interesting solution especially where a space-saving design is necessary.

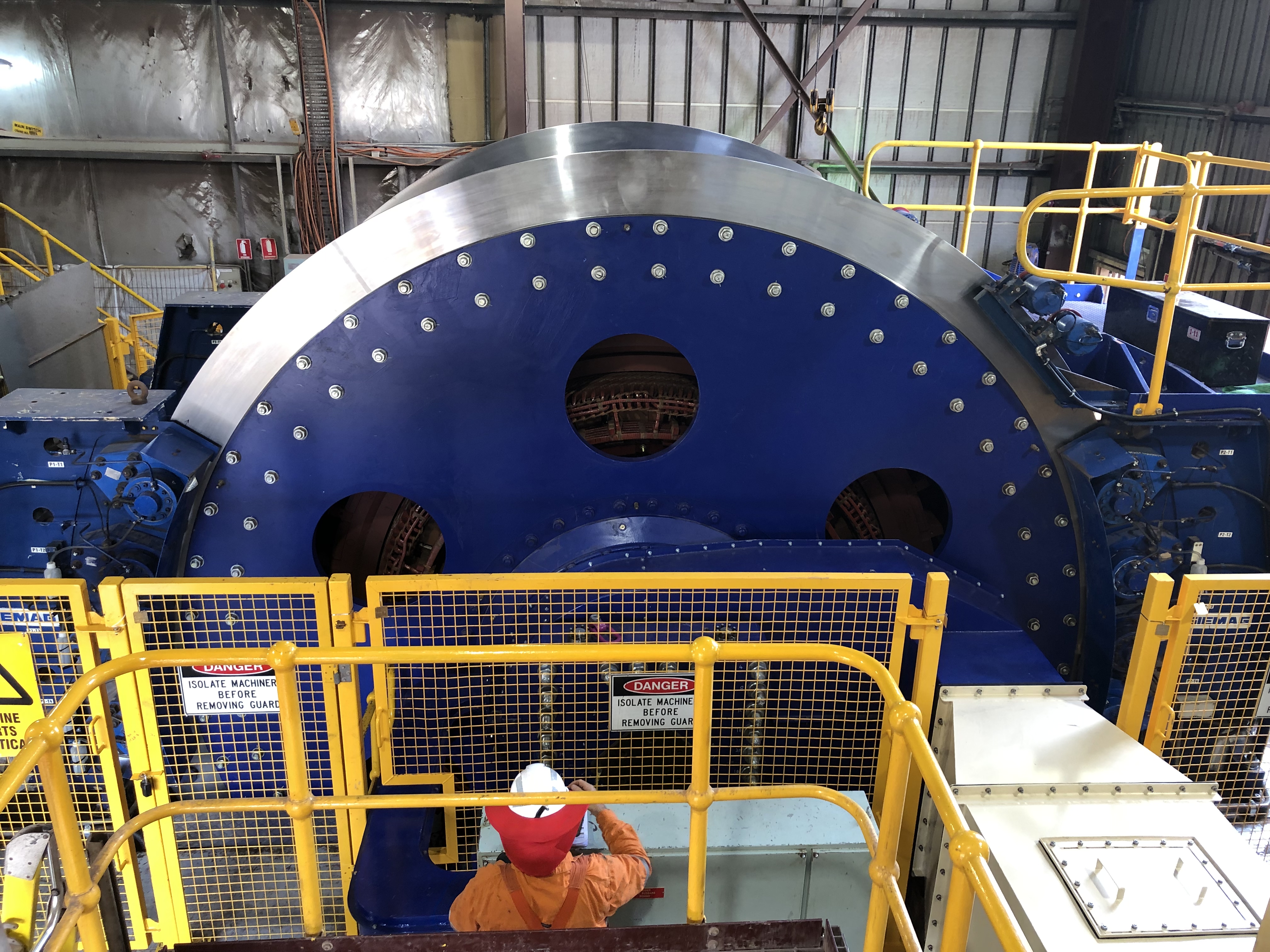

With this drive technology the motor is integrated into the traction sheave instead of being mounted outside on the main shaft, as is the case with conventional KOEPE winding machines. Stator and rotor elements can be accessed through specially provided-for holes in the side plates, which are closed during operation. Cooling air and energy are supplied to the motor via flow rings mounted on the fixed axle.

TECHNICAL FEATURES

- Space-saving and very compact design

- Cost-savings on foundation and construction work

- Marked reduction of conversion and installation times thanks to complete factory assembly and pre-commissioning

- Symmetrical bearing loads

- Symmetrical foundation loads for headframe and floor-mounted machines

- High system stability against magnetic pull

- Robust motor air gap unaffected by external factors

TECHNICAL DATA

- Drum diameter: 4 to 6 m

- Number of ropes: 1 to 6

- Payload: 10 to 50 t

- Operating load: 33 to 305 t

- Drive output: 700 to 9.000 kW

- Shaft depth: 370 to 1,380 m